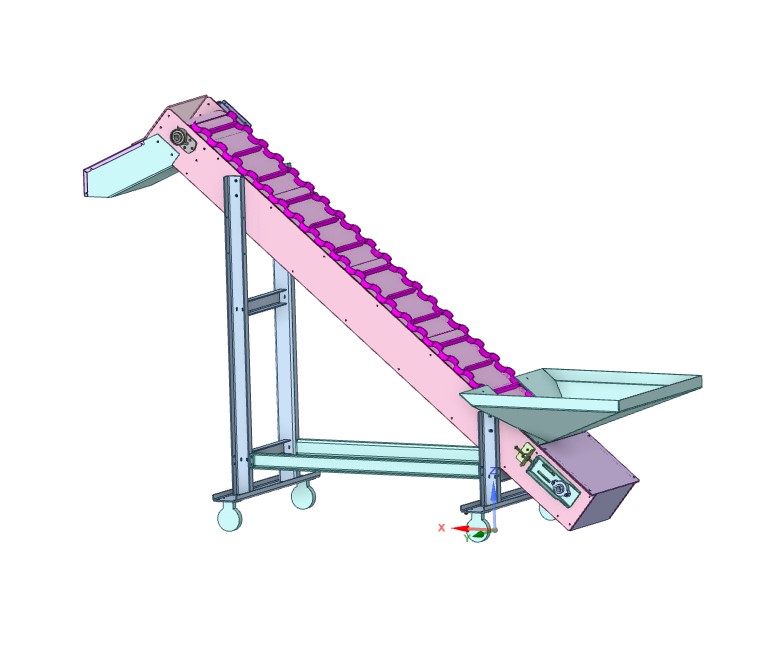

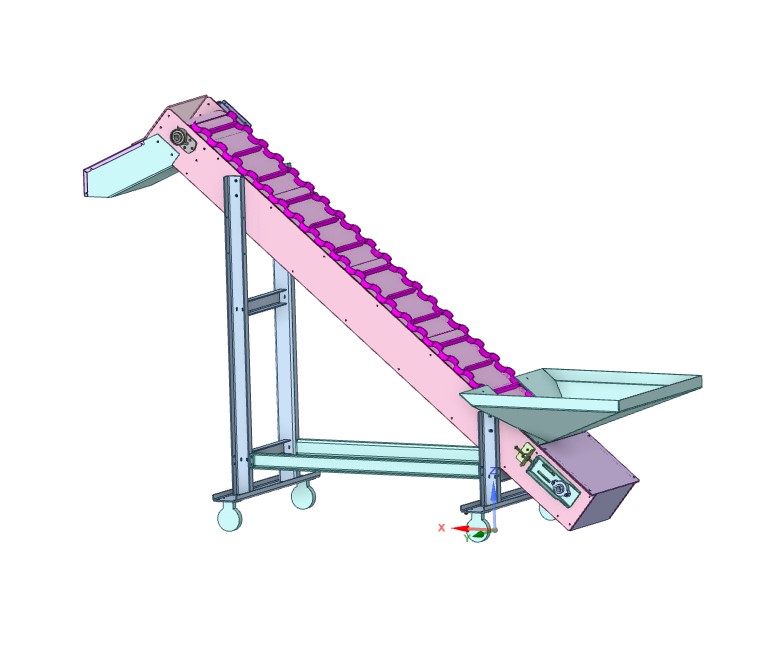

I designed the rubber belt loader to transfer ⅛” rivets, which were too small to be handled by a standard conveyor belt due to the risk of parts getting stuck. This design ensures that the rivets are securely moved without falling back down the conveyor. By using a rubber belt, the system allows for smooth transport while keeping the small parts in place, optimizing the transfer process and preventing jams. This solution improves efficiency for handling small, delicate parts that would otherwise be problematic with hinged belt conveyors.

- Developed initial design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.