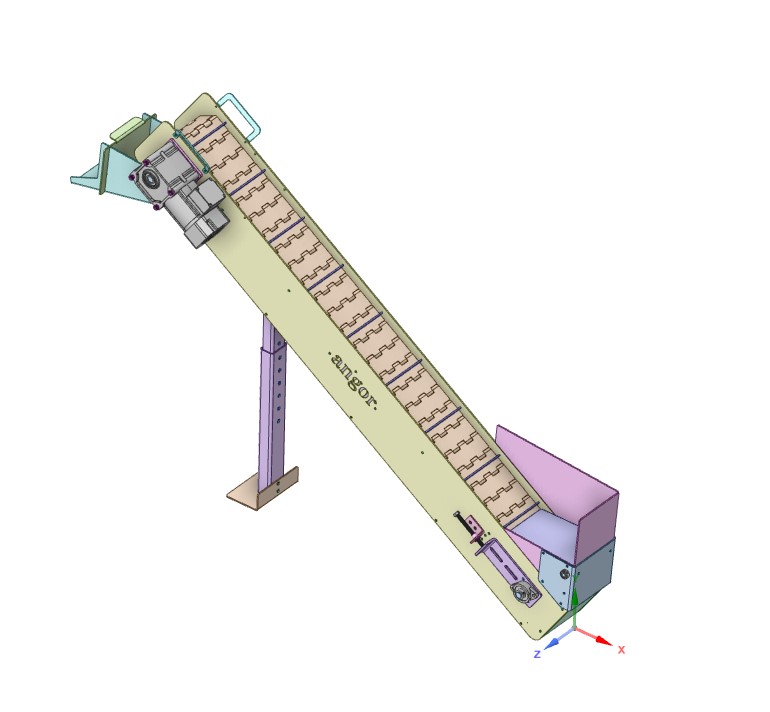

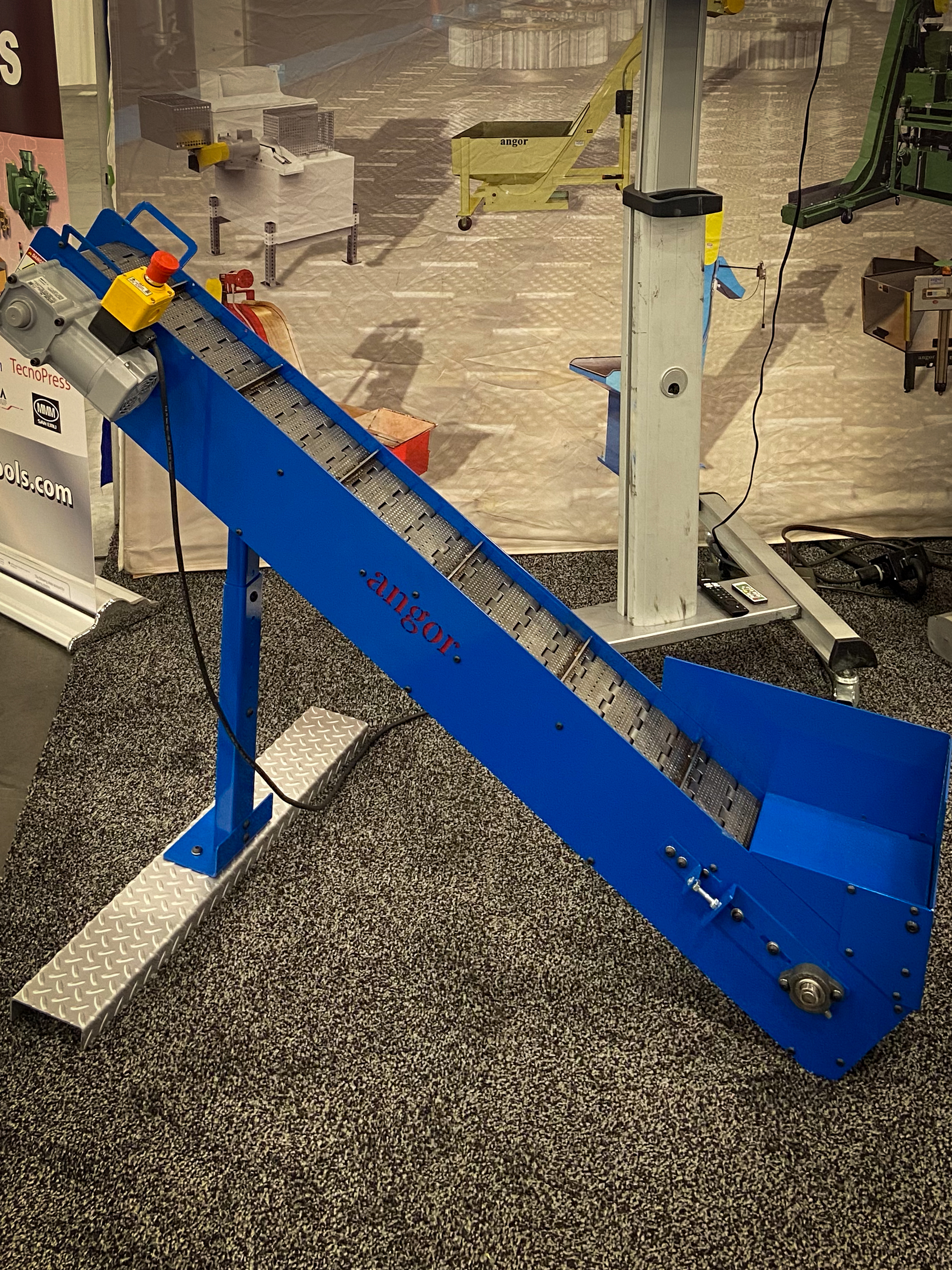

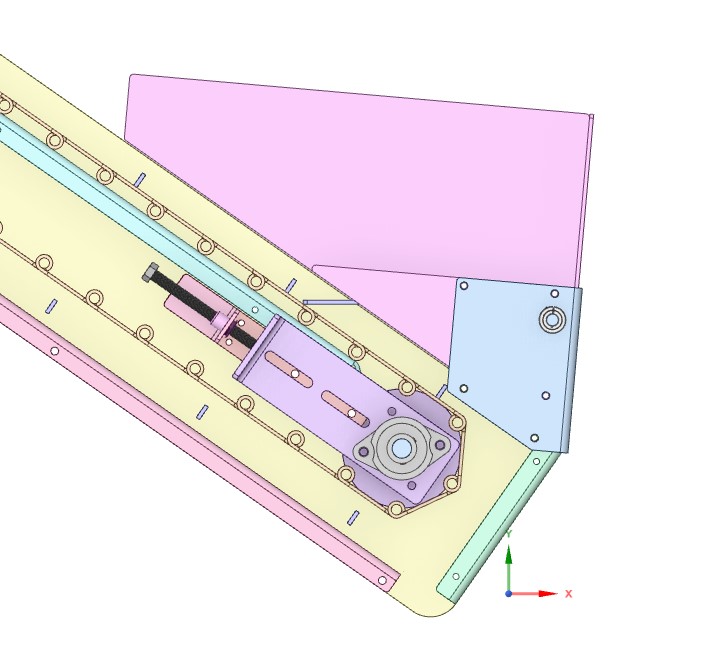

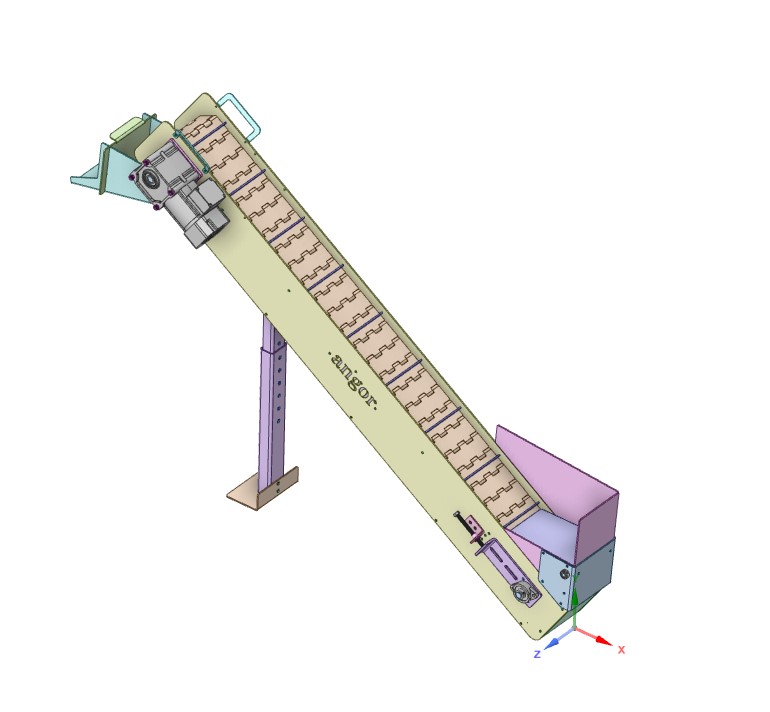

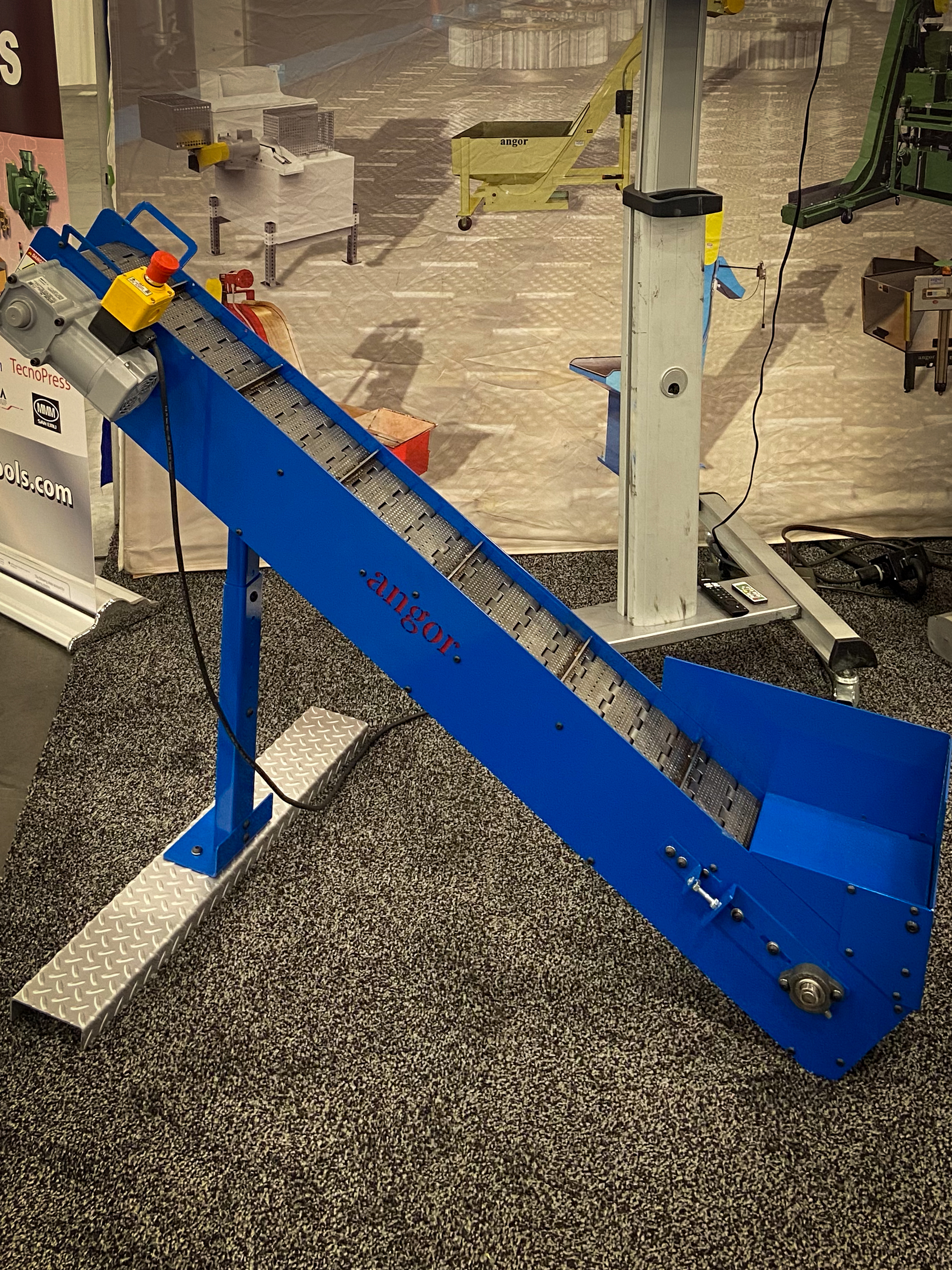

The Econoveyor was engineered to automate the repetitive task of manually moving finished parts into 40" high bins. Designed with a lightweight, bolt-together frame, it’s easy to relocate around the factory floor, providing flexibility wherever it’s needed. To handle oily parts efficiently, the Econoveyor uses a hinged belt and custom sprocket, eliminating the need for a traditional chain. In response to overseas competition, the conveyor’s design emphasizes cost-effectiveness, requiring minimal welding to streamline assembly and reduce production expenses. This low-maintenance, durable conveyor is ideal for handling oiled parts and materials, offering a practical and economical solution for industrial environments.

- Developed initial design concepts for team review and feedback.

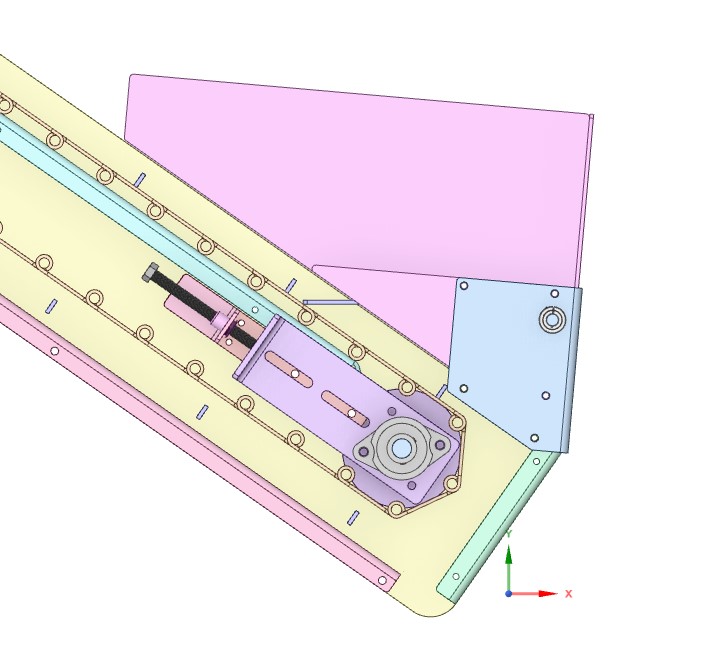

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.