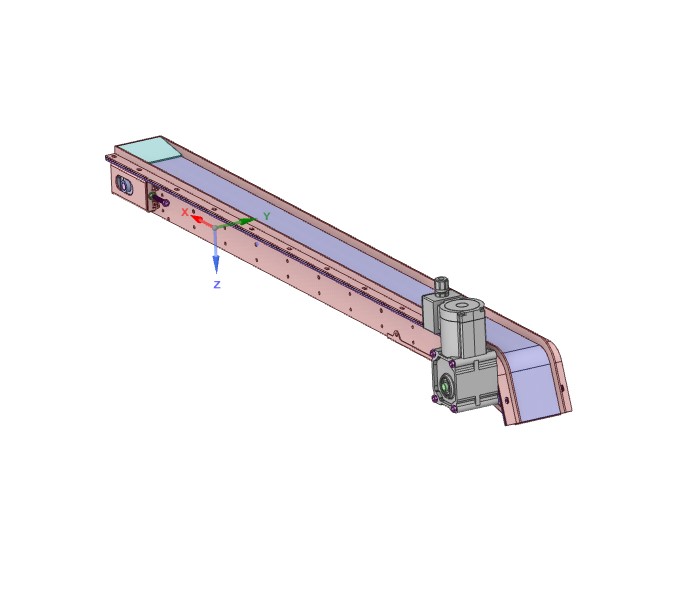

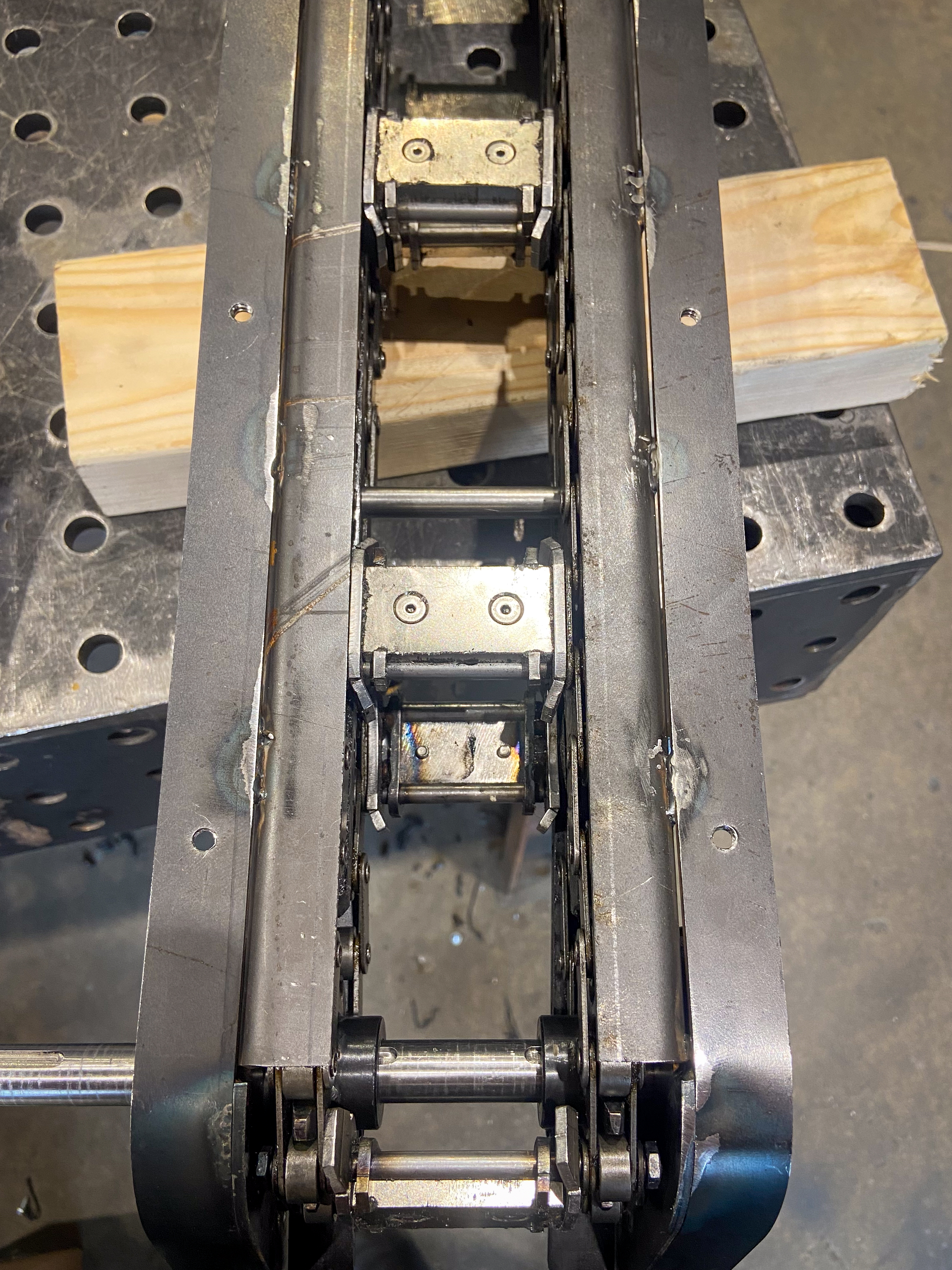

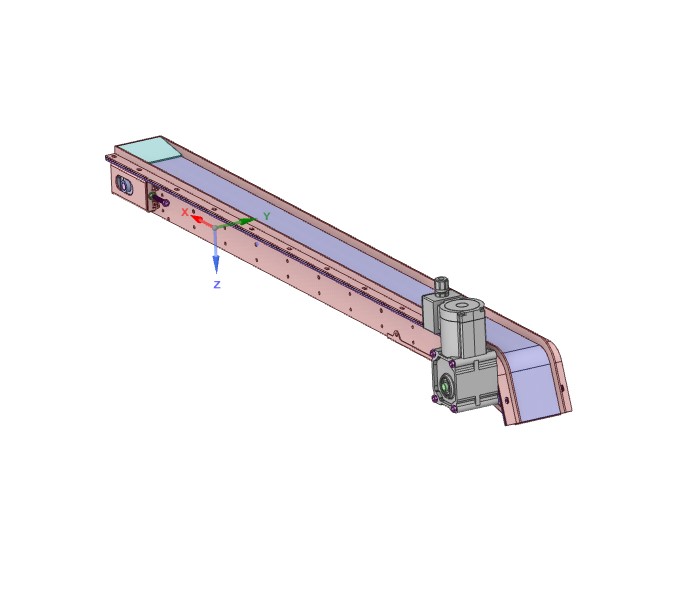

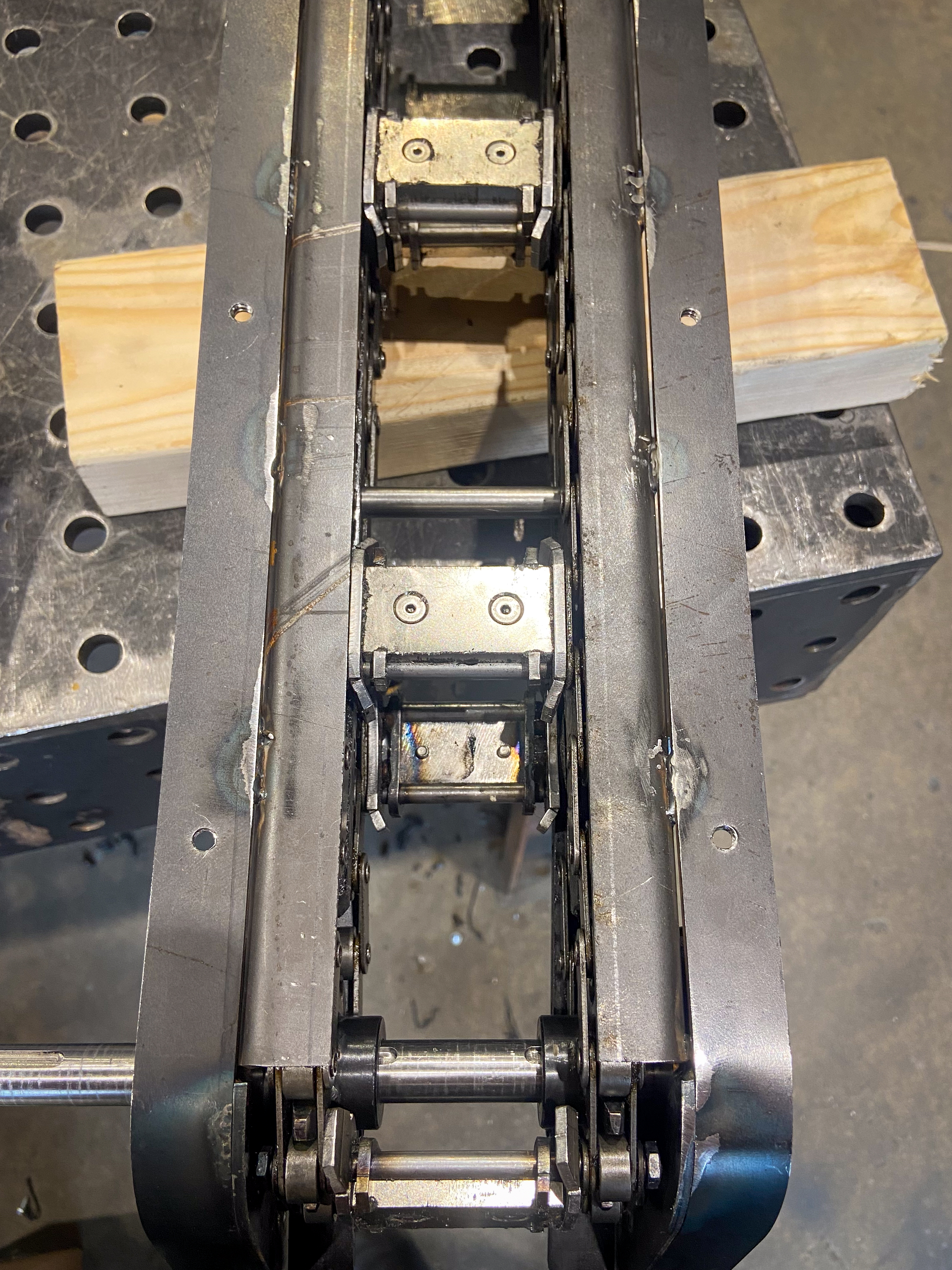

The mini magnetic conveyor is designed to efficiently move ferrous components from under a machine discharge. It features a custom magnetic bar fabricated onto a chain and housed within a precisely toleranced enclosure. This fully enclosed design ensures smooth, uninterrupted operation, unlike exposed metal or rubber belt conveyors that are prone to jams. The conveyor reliably moves metal parts along a rigid stainless steel surface, maintaining consistent performance. Built to fit tight space constraints (4” wide x 6” tall), this compact system offers a space-saving, efficient solution for environments where reliability and space optimization are critical. Every component is custom fabricated to ensure precision and durability.

- Developed initial design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.