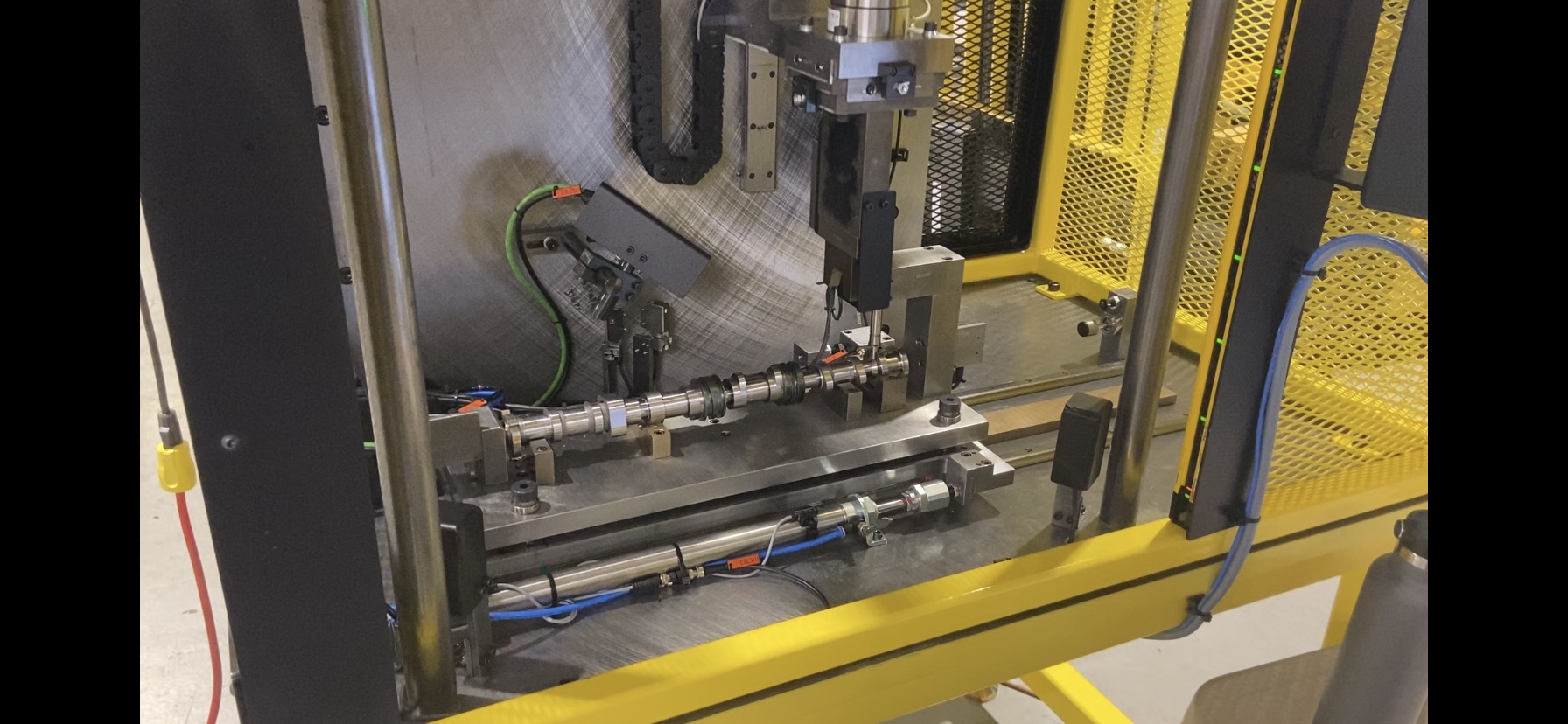

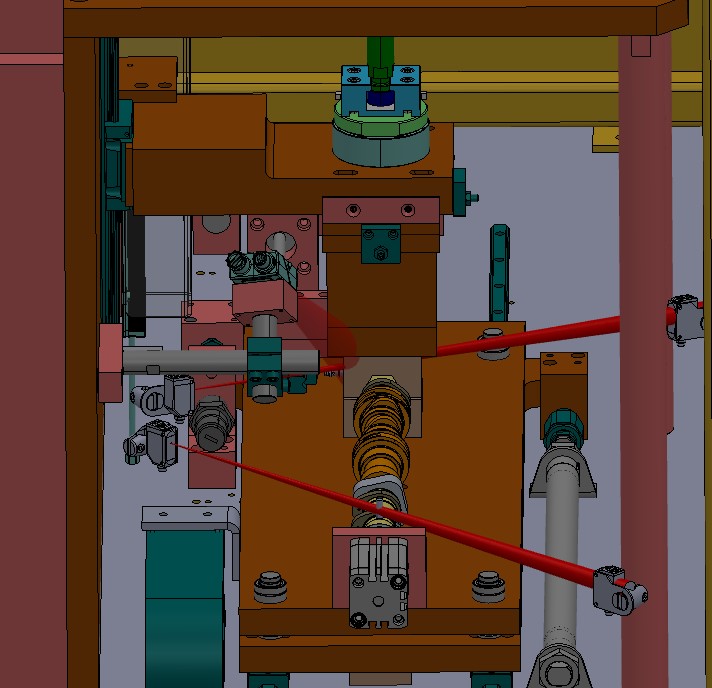

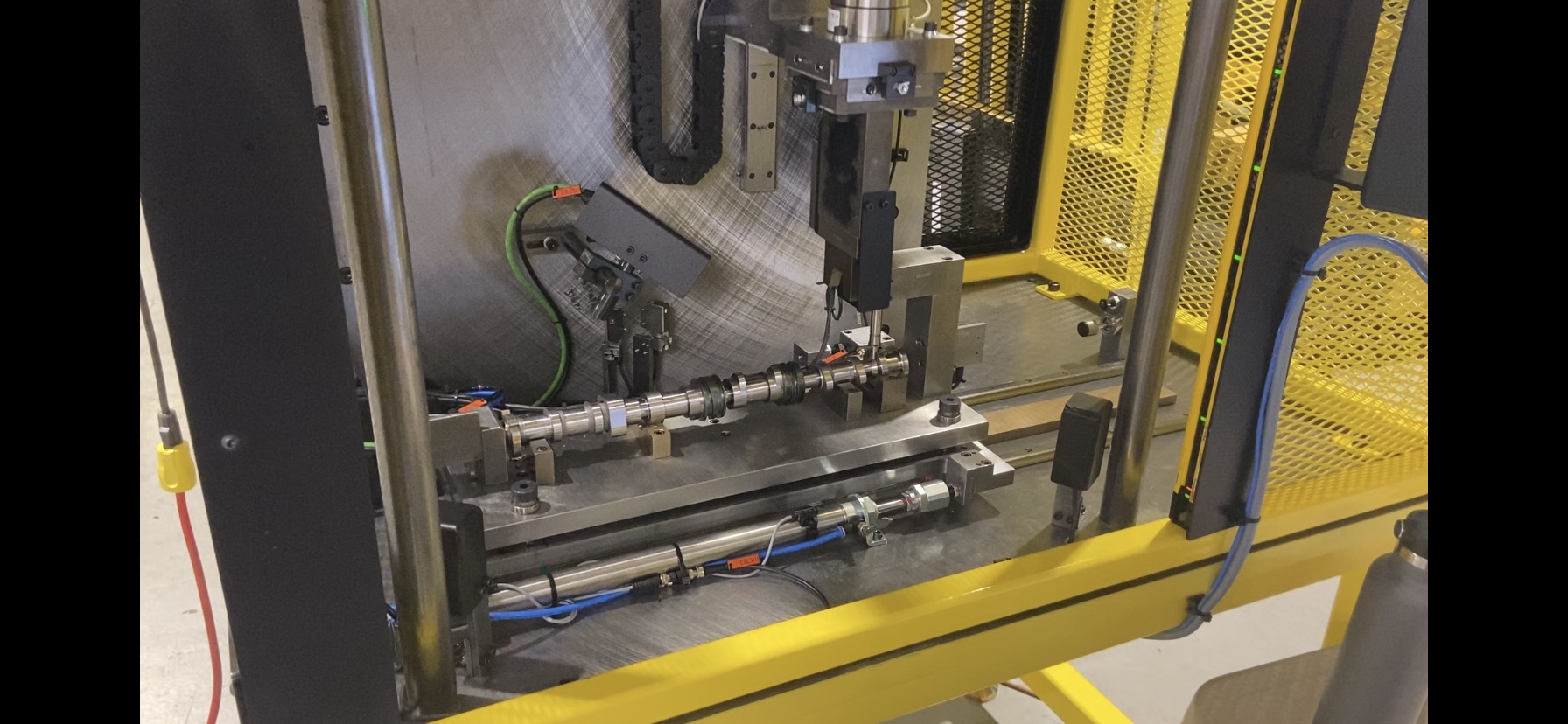

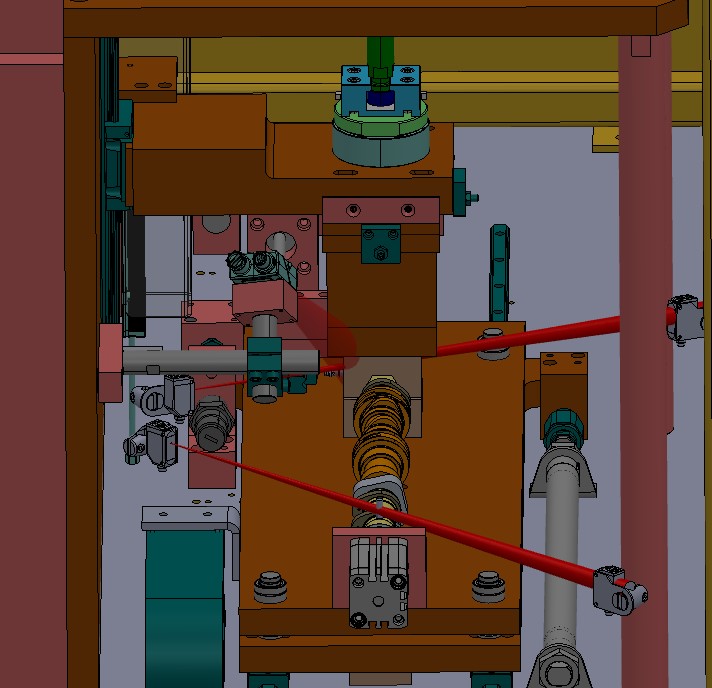

The Camshaft Pin Machine was designed to automate the insertion of two pins into a camshaft with precision. Laser sensors verify pin alignment, while a servo press ensures accurate insertion. Air cylinders move the carriage, facilitating precise pin placement. The system incorporates 250 CNC-machined components and other manufacturing processes like surface grinding, metal fabrication, laser cutting, and flame cutting. This setup enhances production efficiency while maintaining tight tolerances and high-quality standards.

- Developed initial design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.