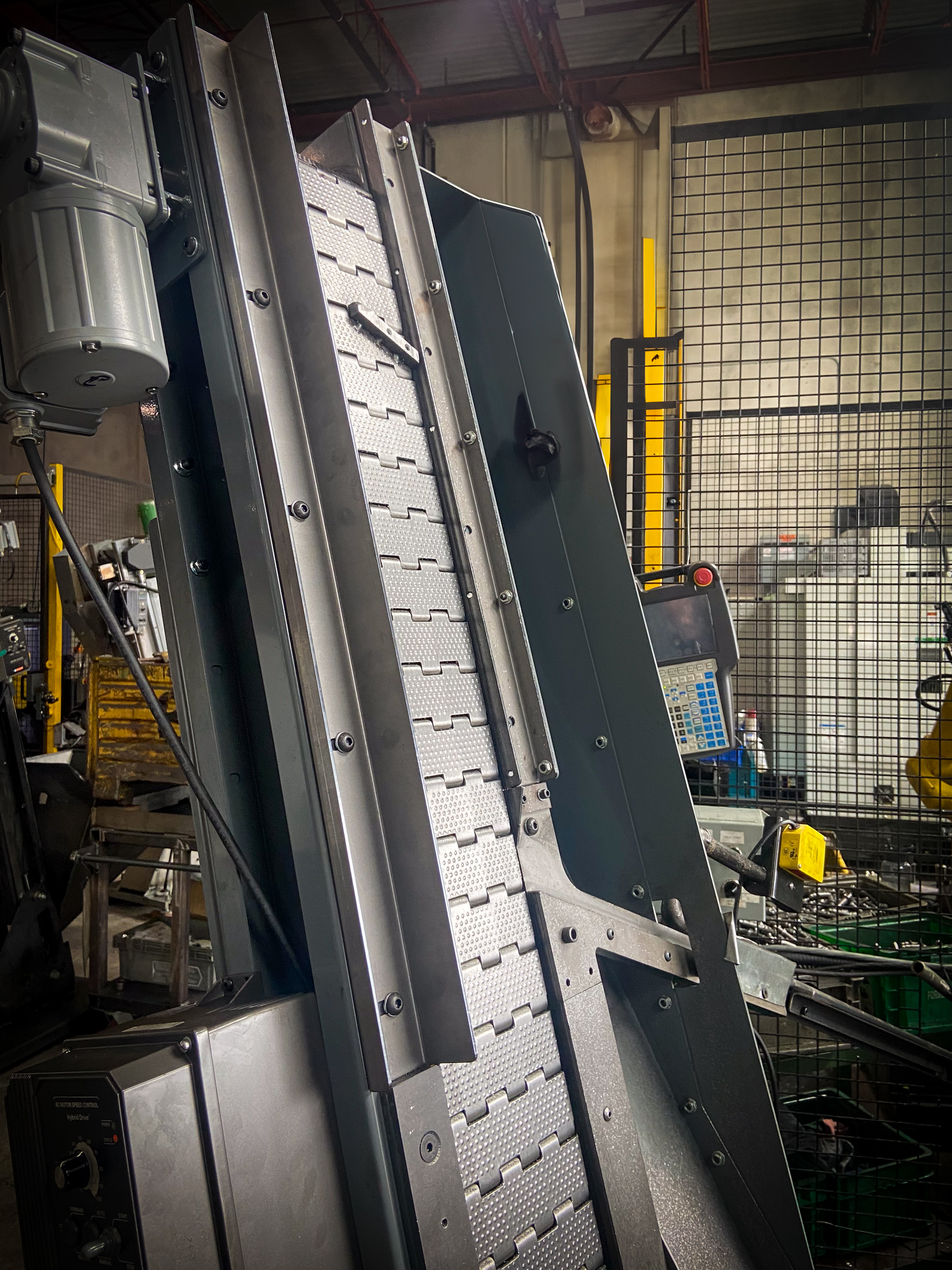

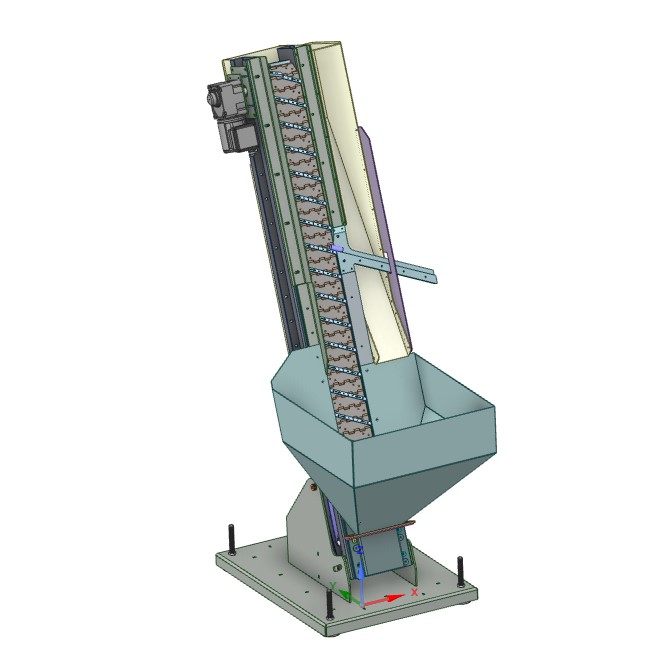

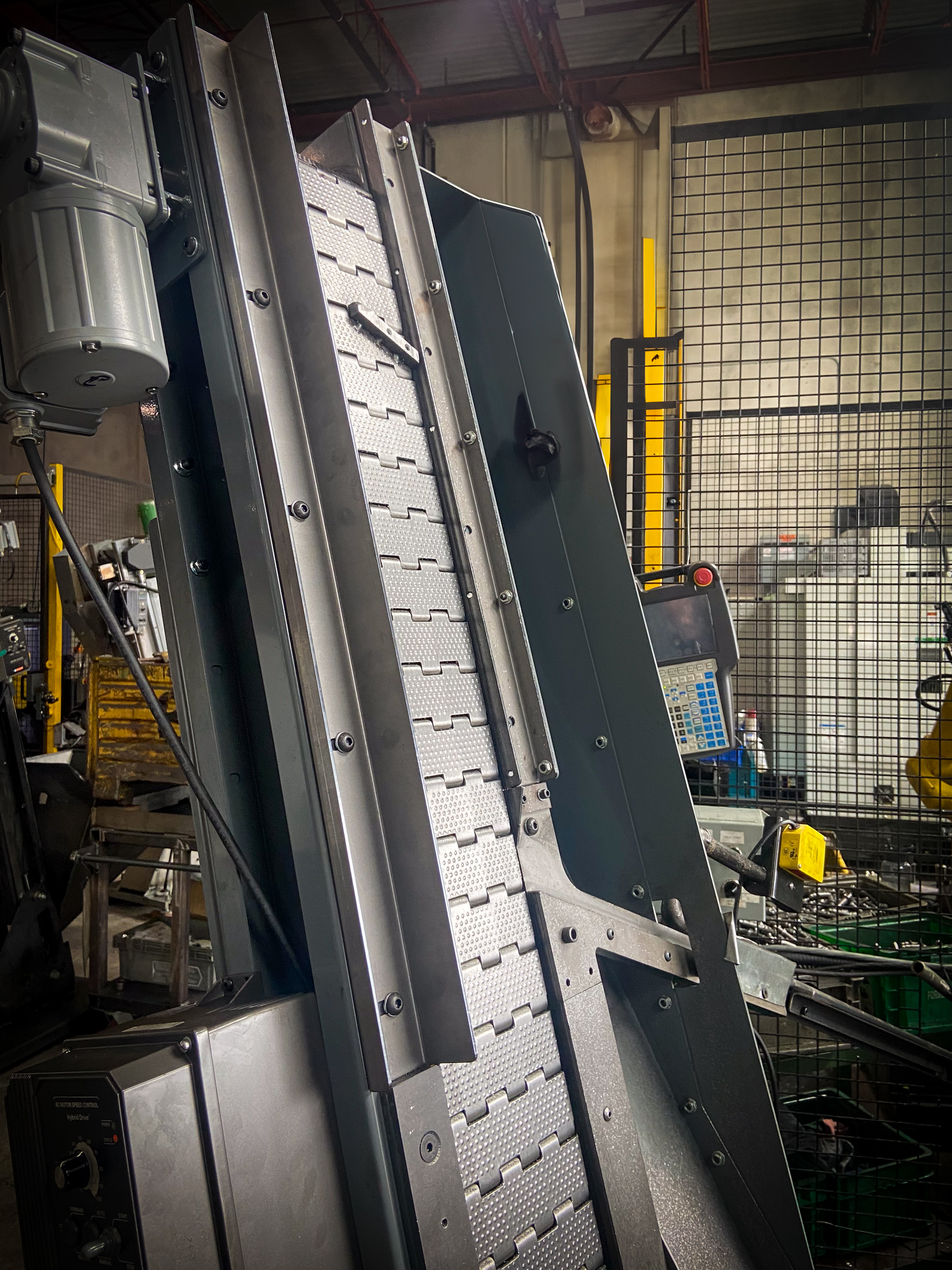

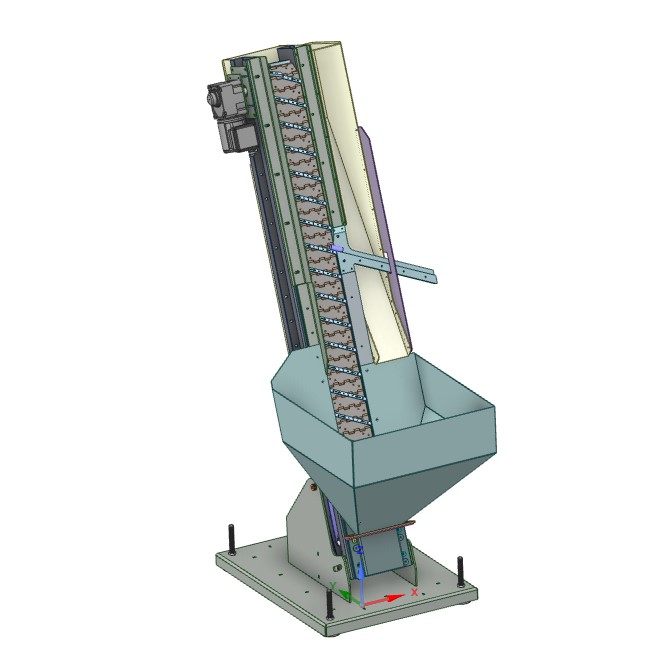

I designed this conveyor to load components into a CNC turning machine using gravity and conveyor cleats, which were angled to guide the parts down a rail and into robot gripper fingers. Unlike typical systems that load parts individually using a vibratory bowl, this design streamlines the process by efficiently feeding components. A hopper feeds parts into the cleats, and the conveyor belt uses a hinged belt design for smooth operation. This setup increases efficiency and reduces manual handling, ensuring continuous and reliable part loading.

- Developed initial 3D design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Managed suppliers, welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting.