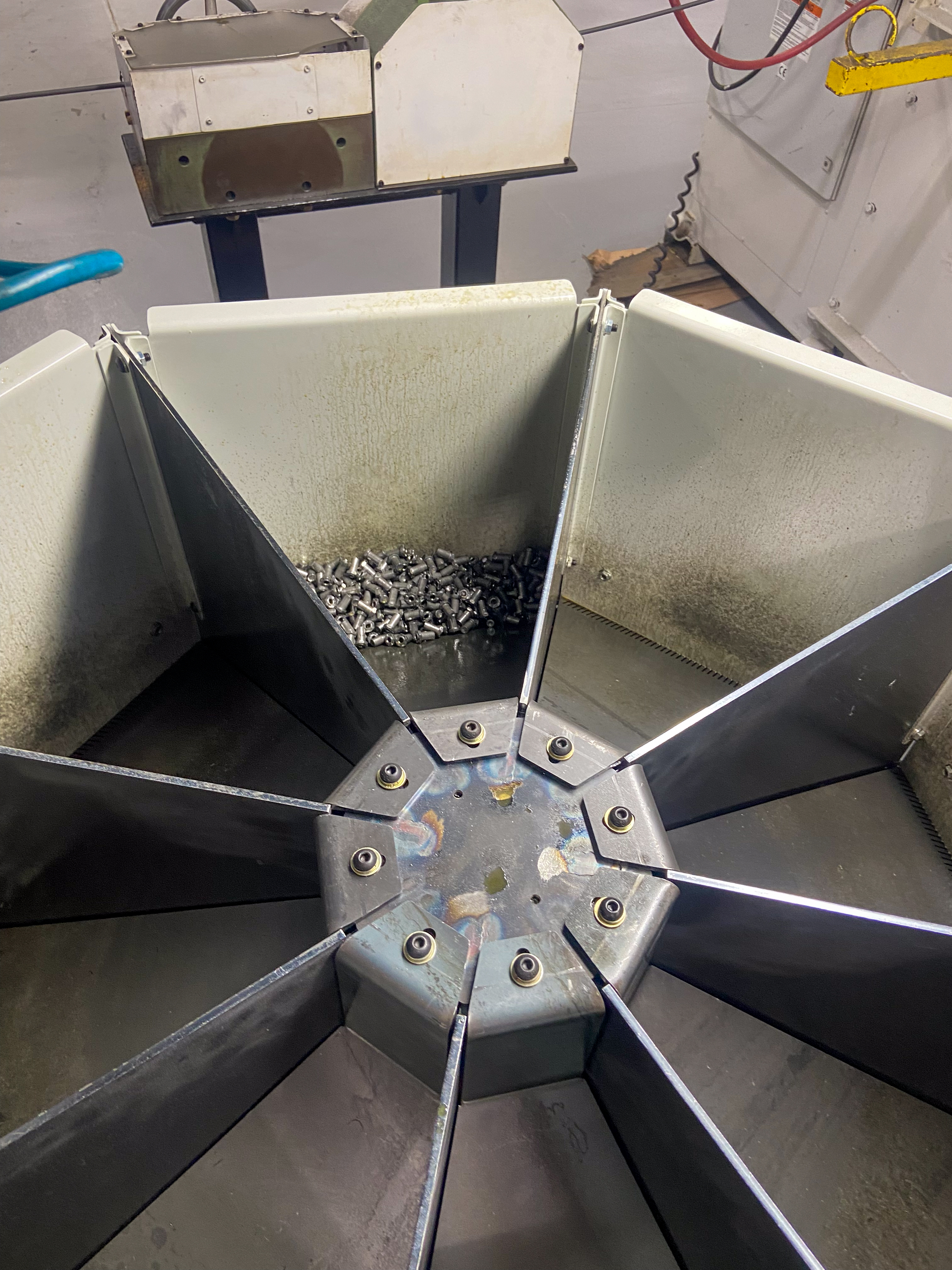

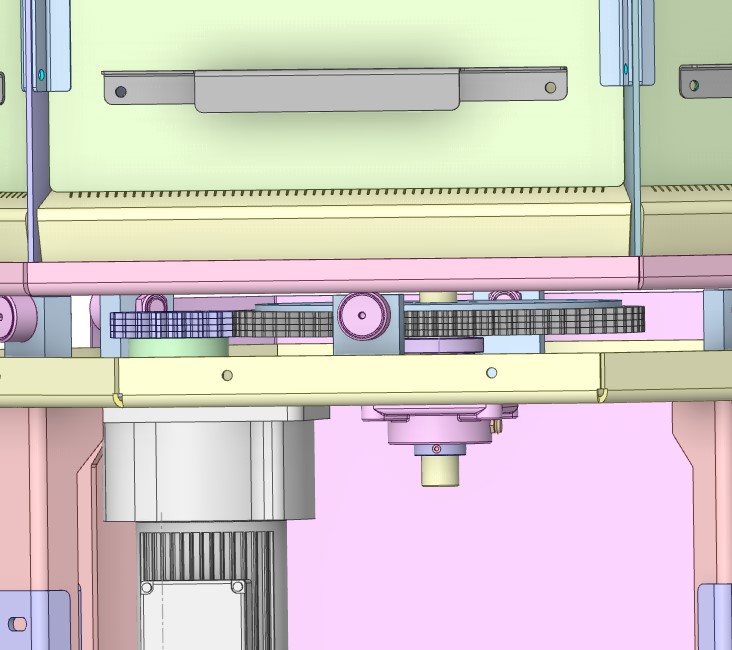

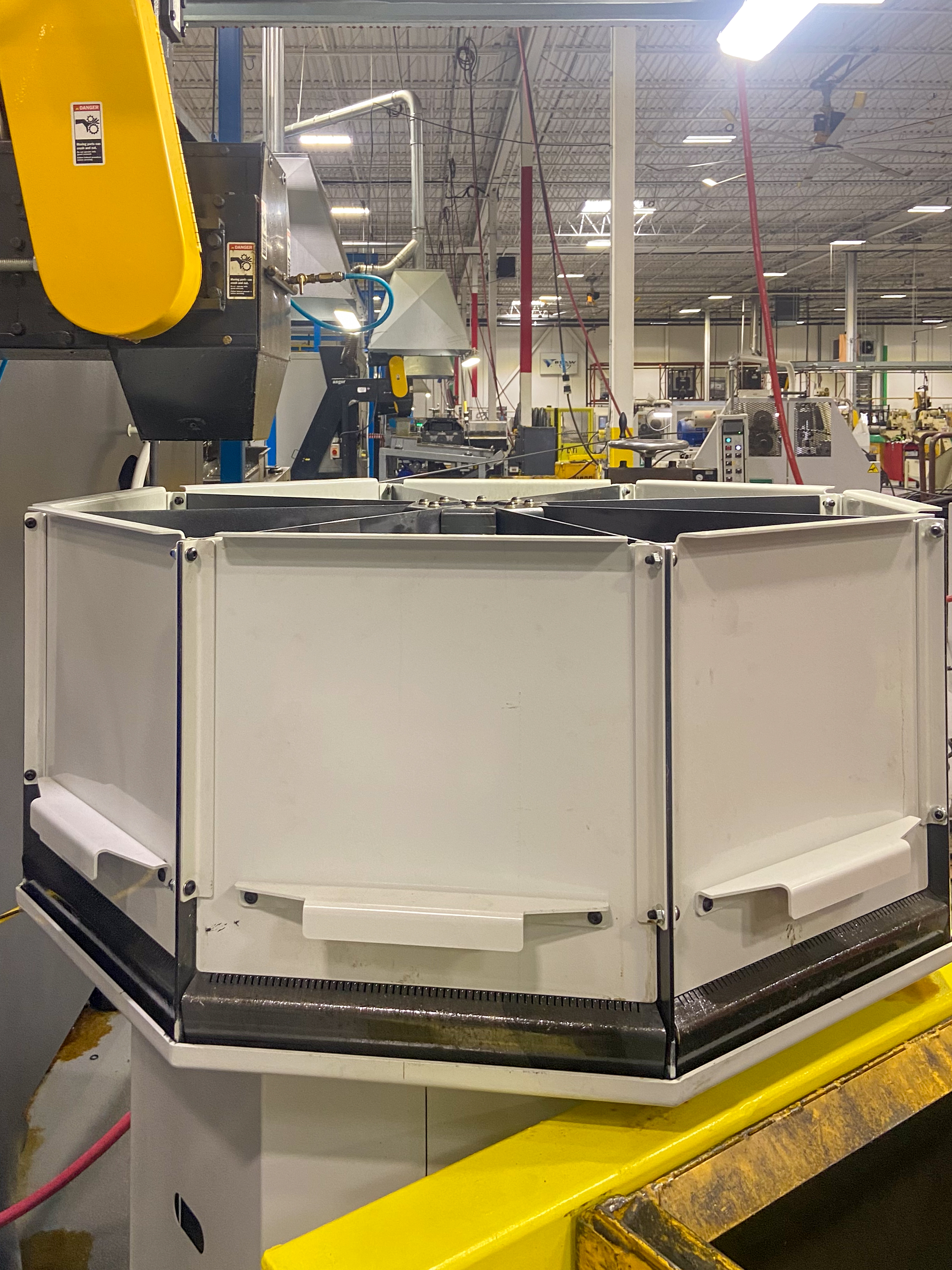

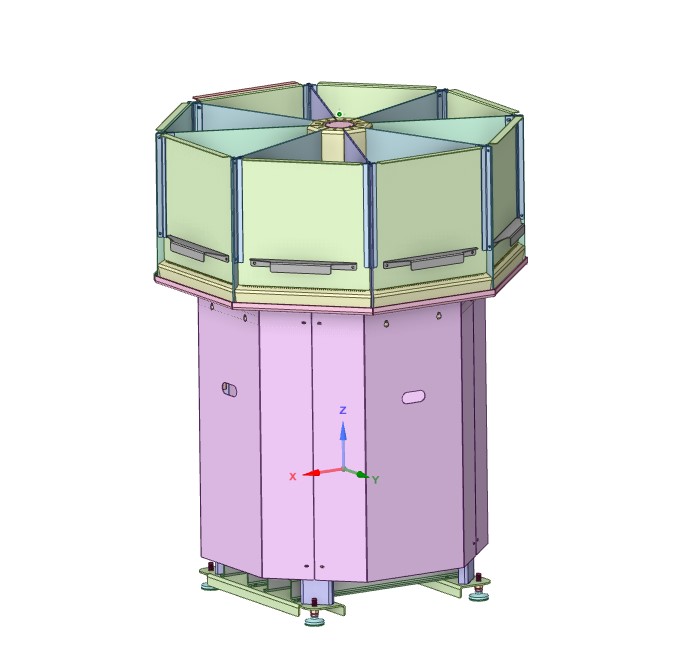

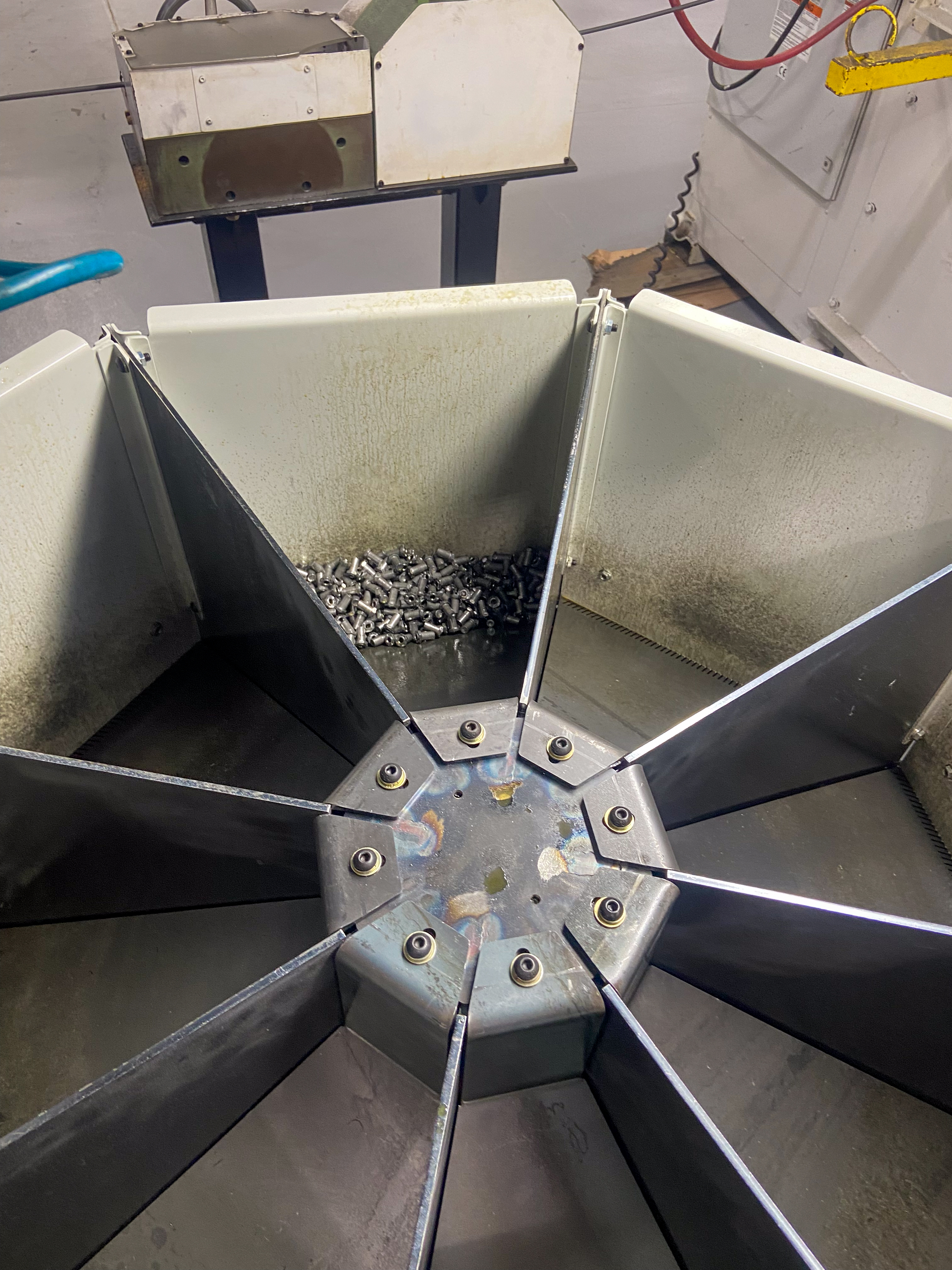

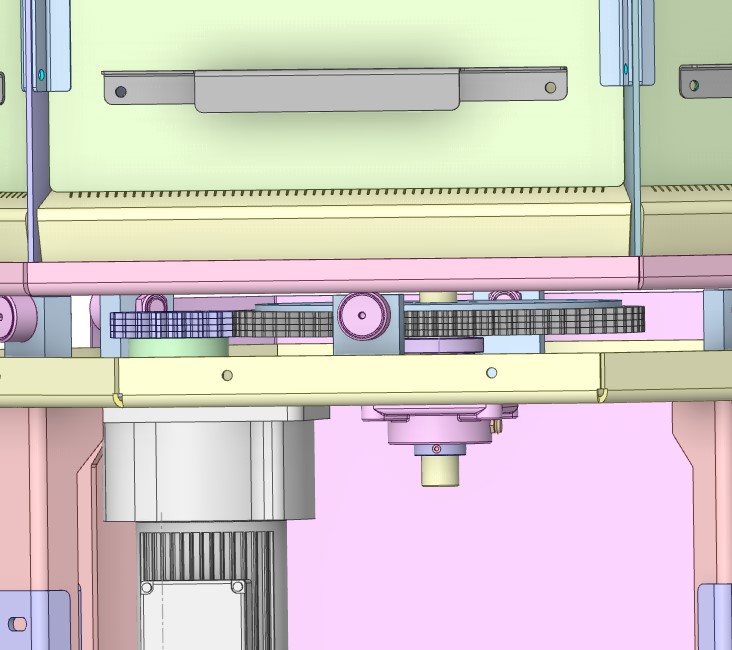

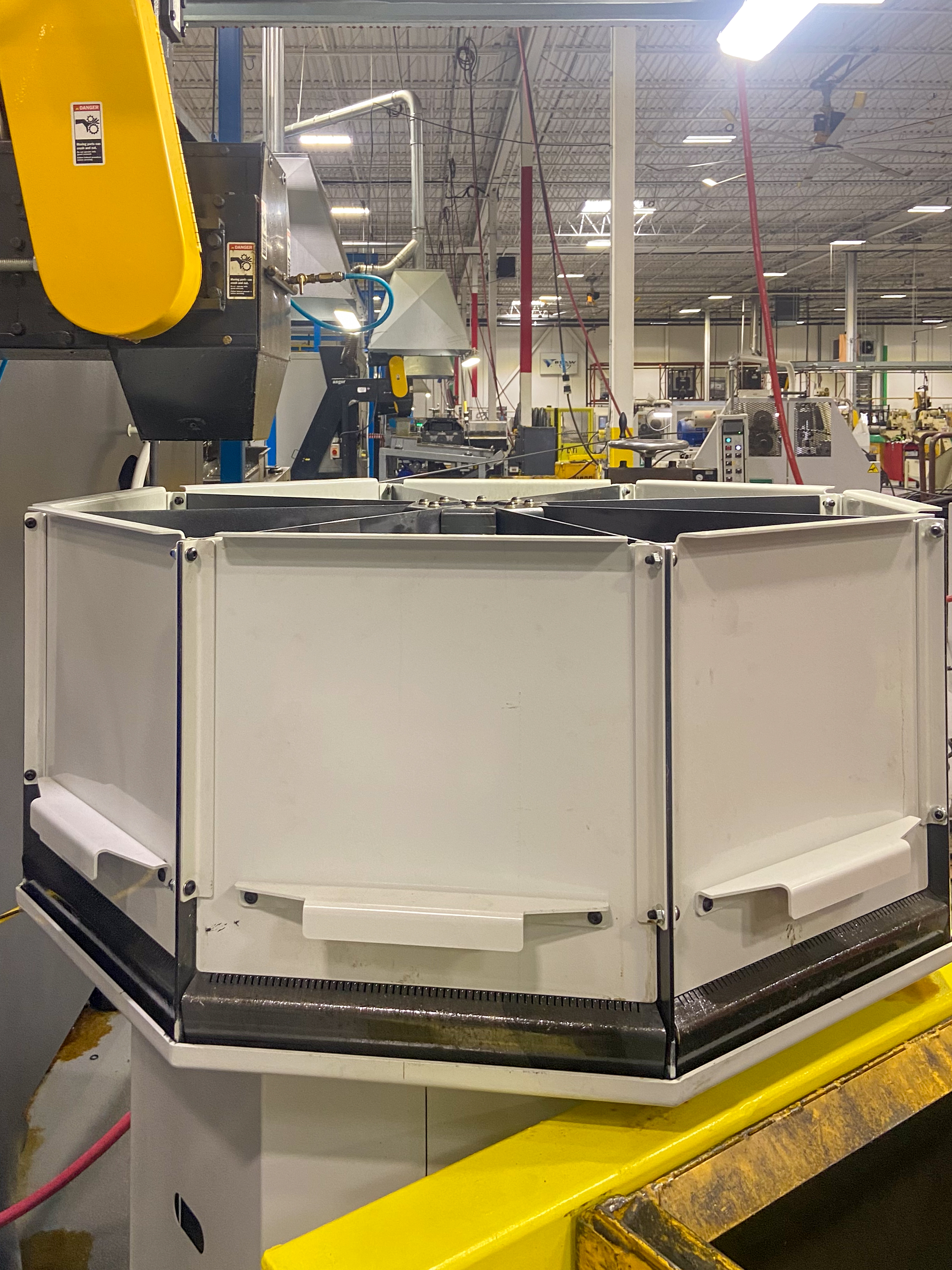

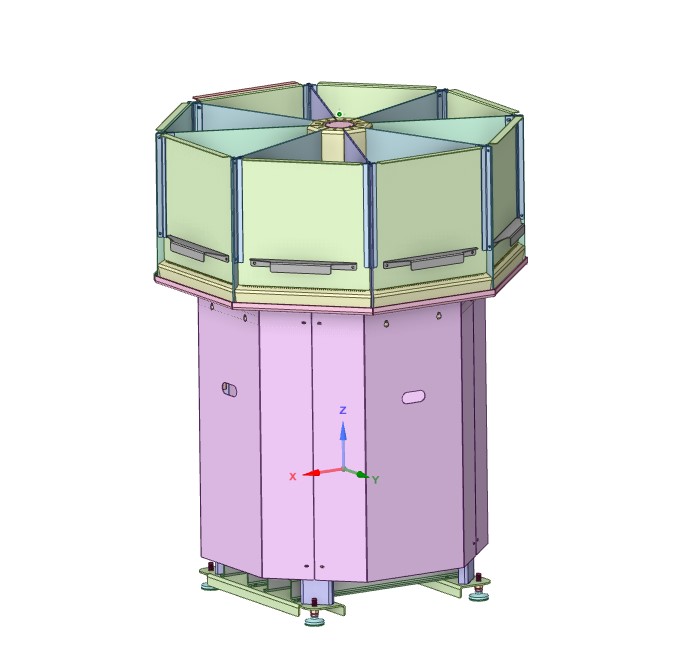

The Automated Rotary Turntable (ART) was engineered to streamline and automate part inspection and sorting. Traditionally, parts are loaded into a single bin by a conveyor, requiring operators to check each bin manually once it’s full. The ART eliminates this repetitive task by automatically distributing parts across eight bins, allowing operators to manage multiple machines and focus on higher-value tasks. Designed specifically for handling oily parts, the ART features built-in oil drainage, with a watertight, welded top table that efficiently collects any oil. Driven by a shaft and spur gears and rotating via camshafts, the ART is fabricated from custom sheet metal and CNC-machined components for precision and durability. Proximity sensors control smooth indexing between bins, keeping parts organized and dry while maintaining a clean, efficient workflow.

- Developed initial design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.