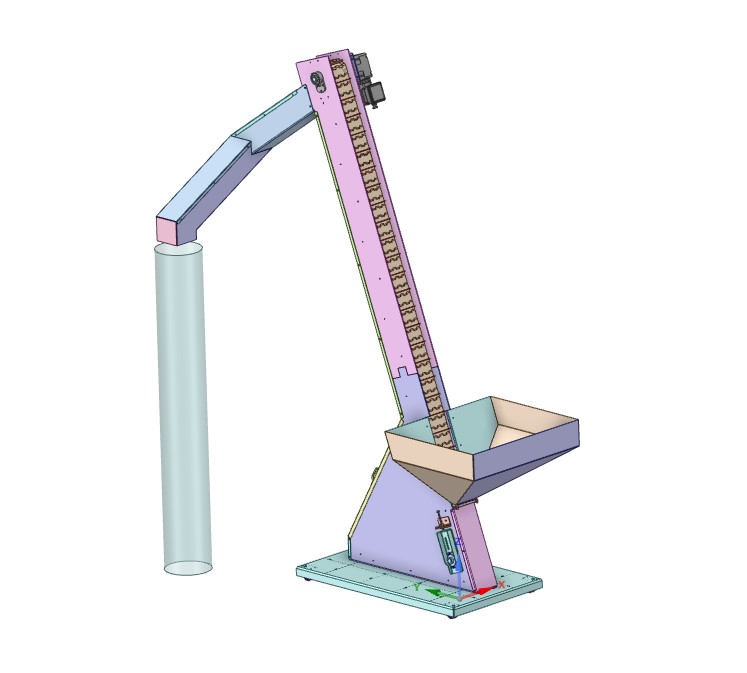

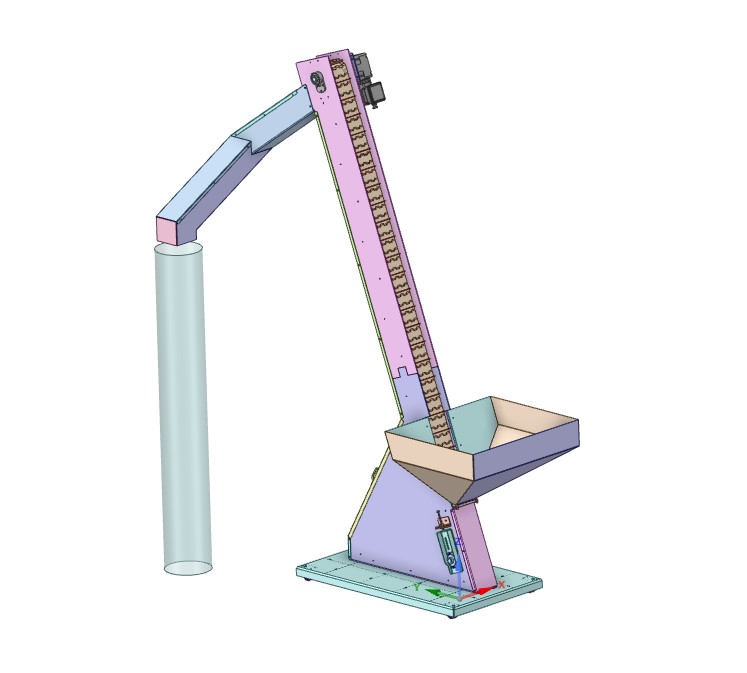

I designed the Econoveyor to take on the repetitive task of moving finished parts from the discharge of a tapping machine into a standard bin, freeing operators to focus on more critical work. It’s engineered to be lightweight, allowing it to be easily moved around the factory as needed. The bolt-together design reduces the need for welding, making it simpler to assemble and keep production costs low. With a sprocket-driven hinged belt instead of a chain, the Econoveyor is also low-maintenance and built to last, providing a cost-effective solution that competes well with overseas alternatives.

- Developed initial design concepts for team review and feedback.

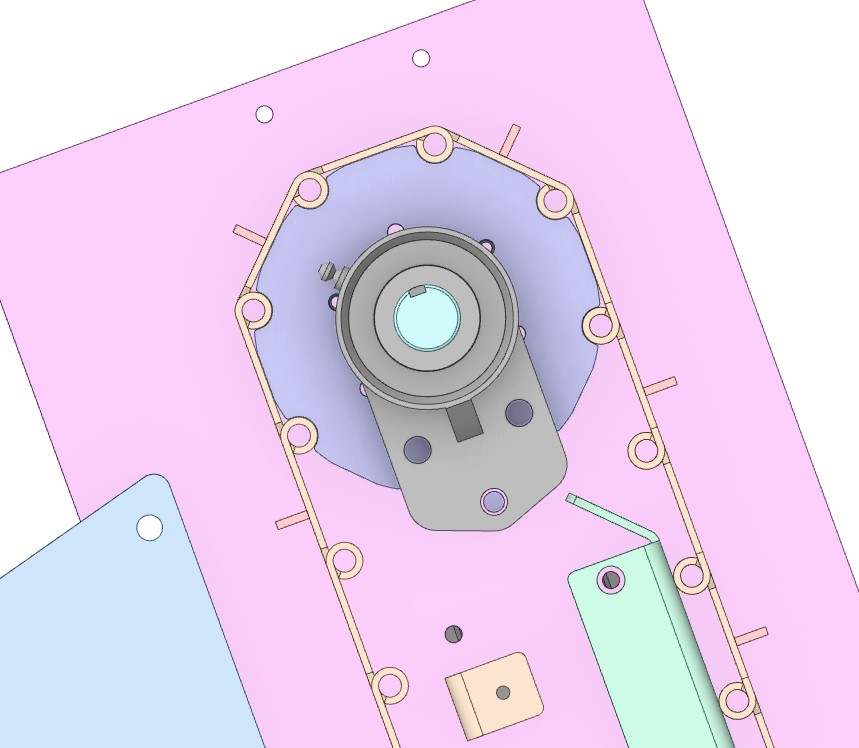

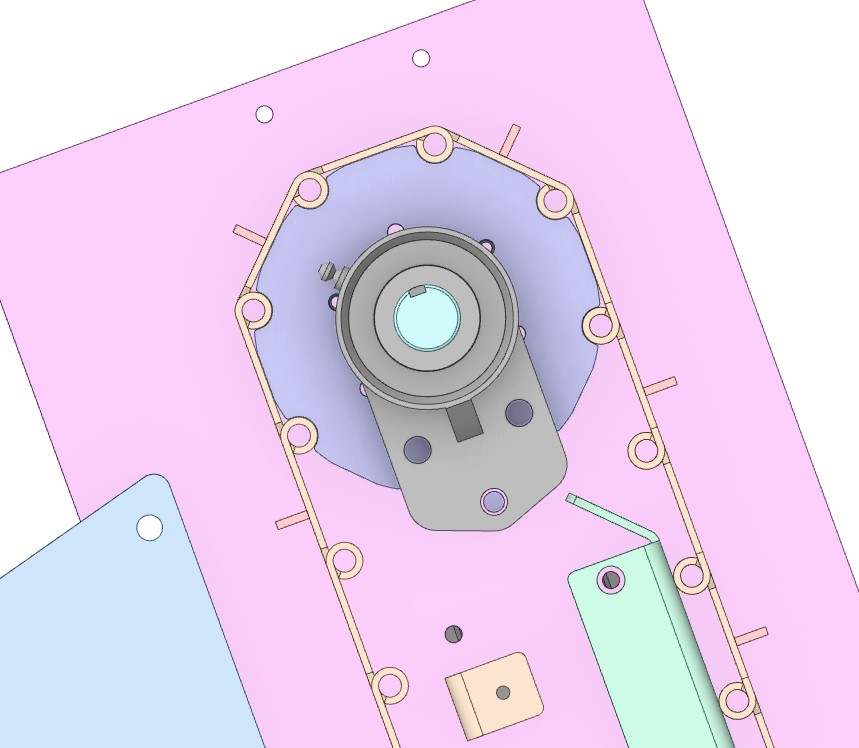

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.