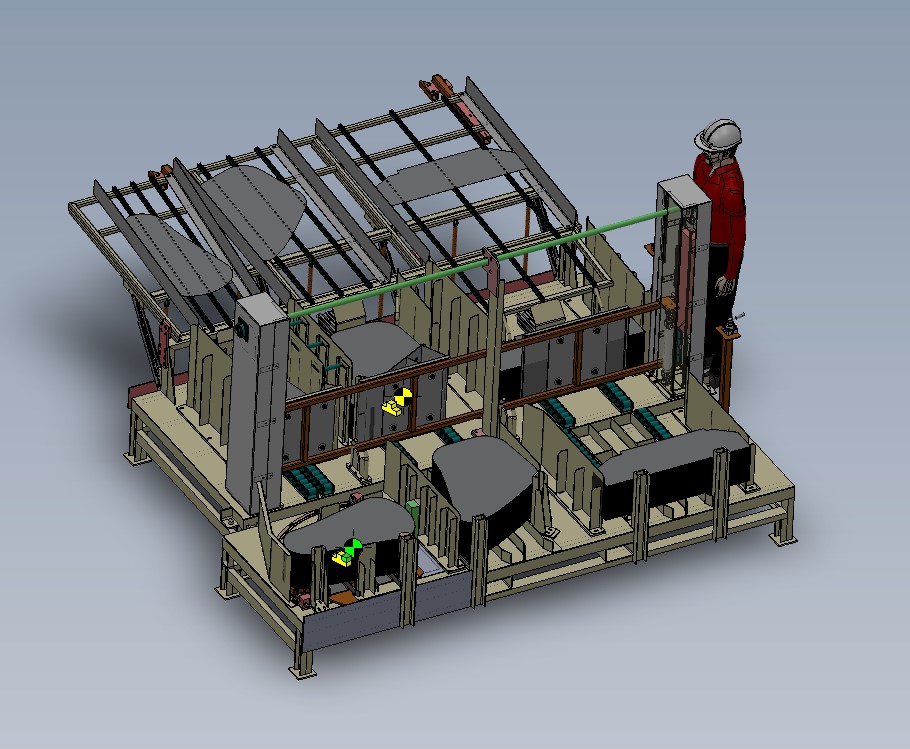

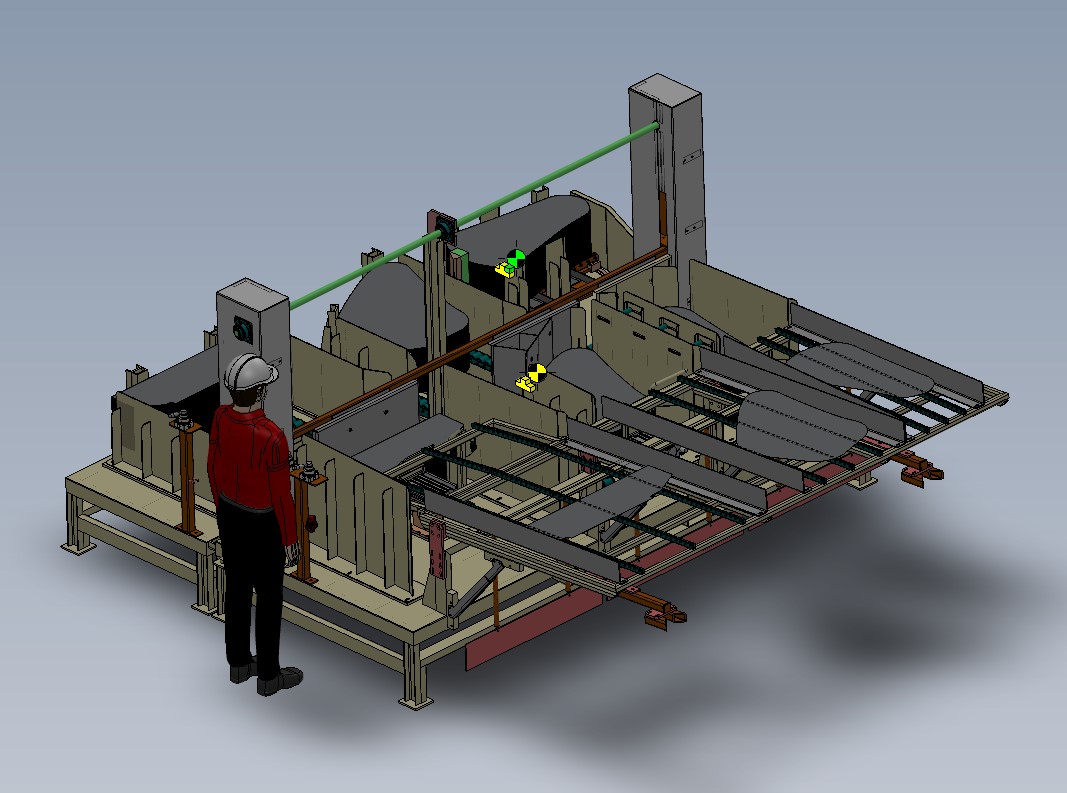

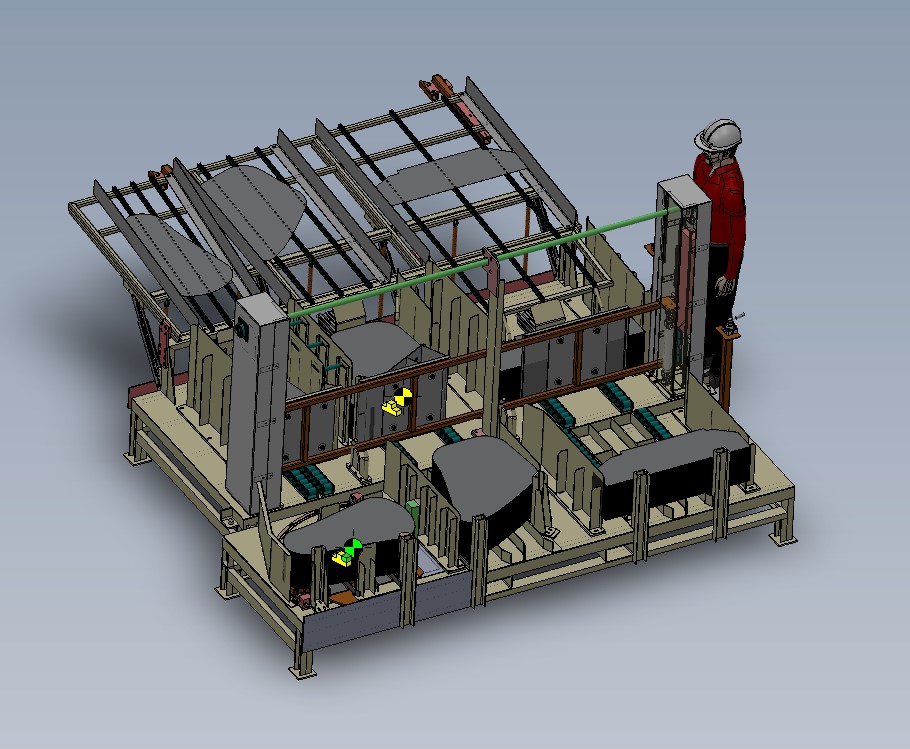

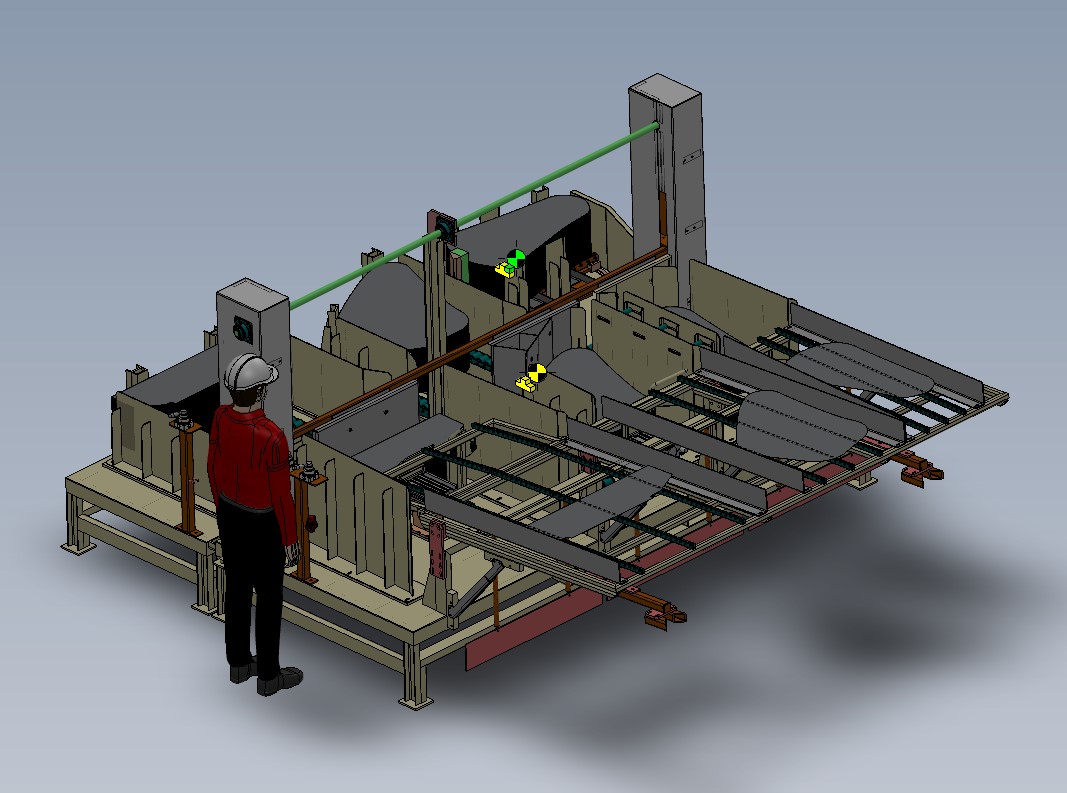

The collector machine was designed collaboratively with two other engineers to handle and transfer car door blanks from a stamping process to subsequent operations. This system discharges the blanks onto an accumulation unit where they stack efficiently. Counterweighted stopping doors, driven by a hydraulic cylinder, hold each blank in place until a stack of 50 is formed. Once complete, the doors open, and an air cylinder pushes the stack forward, allowing easy forklift access for pickup. All components were custom fabricated for precision and durability. This system streamlines the transfer process, enhances operational efficiency, and significantly reduces manual labor on the factory floor.

- Developed initial design concepts for team review and feedback.

- Advanced the concept into a fully manufacturable design, including:

- Sheet metal and machining drawings.

- Bill of materials for purchased components.

- Detailed welding, assembly, and powder coating drawings.

- Led a competitive bidding process to secure the most economical and quality suppliers.

- Coordinated closely with suppliers of CNC machining, laser cutting, and powder coating to ensure high-quality production.

- Managed welding, electrical, and assembly teams to ensure smooth project execution.

- Conducted thorough testing and troubleshooting to confirm operational reliability.